При работе двигателя смесь масляного тумана и картерных газов выталкивается из картера и возвращается во впускную систему. Хотя этот процесс способствует снижению выбросов, он создаёт новую проблему: капли масла попадают во впускной коллектор и постепенно образуют углеродные отложения. Именно здесь… Высокоэффективный фильтр для отделения воды от масла(часто называемый масляным сепаратором или масловоздушным сепаратором) играет важную роль. Он улавливает масляный туман до его попадания во впускной коллектор, поддерживая чистоту двигателя и повышая его эффективность.

Современные турбированные двигатели особенно подвержены рециркуляции масляных паров. Согласно данным испытаний, представленным в многочисленных отчётах автомобильной инженерии, турбированные двигатели генерируют в 2–3 раза больше масляного тумана в системе принудительной вентиляции картера (PCV), чем атмосферные двигатели. Без маслоотделителя впускной коллектор, интеркулер, клапаны и поршни накапливают отложения гораздо быстрее.

Картерные газы содержат мельчайшие капли масла, которые ведут себя иначе, чем жидкое масло. Даже высококачественные системы впуска не могут полностью предотвратить попадание этих микроскопических частиц в камеру сгорания. Со временем пары масла приводят к:

Толстые отложения на впускных клапанах

Снижение эффективности воздушного потока

Увеличение тенденции к детонации

Более низкая эффективность сгорания

Преждевременный износ турбокомпрессора

Исследования показывают, что попадание всего 1 грамма масла во впускной коллектор может снизить октановое число на 1–2 пункта из-за взаимодействия масла с топливом, увеличивая вероятность предварительного зажигания в современных двигателях с непосредственным впрыском.

Маслоотделители улавливают пары до их затвердевания в виде углерода. Это снижает частоту очистки:

Впускной коллектор

Клапаны

Поршни

Интеркулер и дроссельная заслонка

Данные по автопаркам показывают, что автомобили, оснащенные маслоотделителем, за 50 000 миль пробега выделяют на 45–70 % меньше углерода.

Загрязнение маслом нарушает состав топливовоздушной смеси. Удаление избыточных паров масла приводит к:

Более стабильный холостой ход

Улучшенная эффективность сгорания

Незначительное улучшение экономии топлива (0,5–2%)

Более плавное ускорение

Этот эффект особенно заметен в турбированных двигателях, где точность расхода воздуха имеет решающее значение.

Избыток масла в интеркулере снижает эффективность охлаждения, покрывая внутренние стенки. Результаты испытаний показывают, что масляная плёнка толщиной всего 0,1 мм снижает эффективность теплопередачи на 12–18%.

Качественный фильтр для отделения воды и масла для двигателей с турбонаддувом:

Поддерживает чистоту интеркулеров

Уменьшает горячие точки

Защищает турбоподшипники

Поддерживает более стабильные уровни усиления

Это эффективно продлевает срок службы турбокомпрессора.

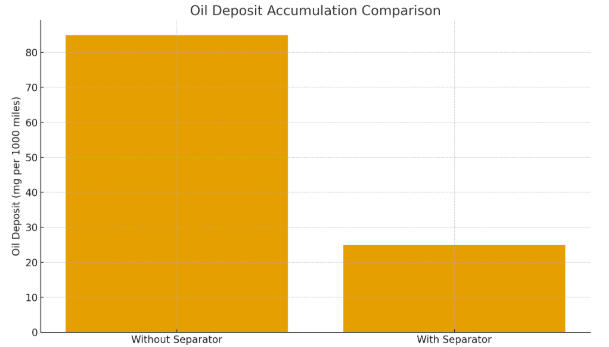

На рисунке ниже показано сравнение отложений масла на 1000 миль с масляным сепаратором и без него (пример данных промышленных испытаний):

Как показано, установка Фильтр для отделения воды от автомобильного масла значительно снижает количество масла, попадающего во впускную систему, помогая поддерживать более чистую среду сгорания.

Капли масла, налипающие на воздухозаборники, уменьшают эффективный диаметр воздушного потока. Согласно стендовым испытаниям на воздушный поток:

Масляная пленка толщиной 0,5 мм уменьшает поток воздуха до 8%

Накопление углерода в сочетании с маслом снижает поток воздуха на 11–15%.

Маслоотделитель поддерживает:

Более чистые впускные каналы

Более точные показания датчика массового расхода воздуха

Лучшая реакция дроссельной заслонки

Автомобили, часто перевозящие грузы, едущие в гору или работающие на высоких оборотах, производят больше картерных газов. Двигатели этой категории наиболее эффективны при использовании систем маслоотделения.

Маслоотделители настоятельно рекомендуются для:

Турбированные бензиновые двигатели

Двигатели с непосредственным впрыском (GDI)

Двигатели грузовиков и внедорожников под большой нагрузкой

Модифицированные/тюнингованные автомобили

Модели производительности (EcoBoost, TFSI, GDI, T-GDI и т. д.)

Вовсе нет. Большинству моделей требуется только:

Опорожняйте канистру каждые 3000–5000 миль

Периодически очищайте фильтр или внутреннюю перегородку.

Ежегодная замена уплотнительных колец (при необходимости)

Техническое обслуживание занимает менее 5 минут и позволяет избежать тысяч ремонтов в будущем.

Маслоотделитель — это небольшой компонент, который существенно влияет на долговечность и производительность двигателя. Предотвращая обратный поток паров масла во впускной коллектор, он помогает снизить образование нагара, улучшить воздушный поток, защитить турбокомпрессоры, стабилизировать сгорание топлива и значительно снизить расходы на долгосрочное обслуживание. Для двигателей с турбонаддувом, непосредственным впрыском и высокопроизводительных двигателей это одно из самых экономичных усовершенствований.

Наши часы работы

Пн 21 ноября – Ср 23 ноября: 9:00–20:00

Чт 11/24: закрыто - С Днем благодарения!

Пт 25 ноября: 8:00 - 22:00

Сб 26.11 - Вс 27.11: 10:00 - 21:00

(все часы указаны по восточному времени)